Conduit and Cables Exposed to Sunlight on Rooftops

By: Daryl Wolfram | Sep 25, 2019

The 2017 NEC method for calculating rooftop installed conductors

Section 310.15(B)(3)(c) Correction Factors

Anyone who has been on top of a roof on a hot summer day knows what it’s like to stand in the middle of an oven. Extreme temperatures from the sun can bake everything in sight, from shingles to appliances, and even electrical conductors and conduit.

Conductor insulation is meant to provide long lasting protection from expected heat due to the flow of electricity and normal environmental factors. However, excessive heat from solar radiation can damage conductors and cause premature failures.

Electricians may wonder how additional heat from the sun impacts rooftop conductor and conduit installations. Does heat from the sun change permitted ampacity of conductors? Depending on conduit placement, conductor ampacity may be greatly reduced because of solar radiation on rooftops. Proper planning of conduit heights before installing conductors on rooftops may lead to significant financial savings.

Preparing for Rooftop Conductor Calculations

To see how conduit placement affects rooftop ampacity, the following information is needed:

- Type of conductor that will be installed

- Termination ratings

- The number of conductors that will be placed in the conduit

- Ambient temperature of the location

- How high above the roof the conduit will be placed

Temperature Ratings of Conductors

Each type of conductor will have its own temperature rating based on the type of insulation that surrounds the wire. The higher the temperature rating, the higher the permitted conductor ampacity. Typically, wire insulation is rated at 60oC, 75oC, or 90oC. A conductor that is rated for 90oC can safely handle more ampacity than a conductor rated at 60oC.

The difference between copper and aluminum (or copper-clad aluminum) conductors also makes a difference in determining permitted ampacities. Aluminum conductors heat up faster than copper conductors because aluminum has a higher resistance to electricity than copper. Therefore, aluminum wire that is the same size as copper has lower ampacity ratings.

Termination Ratings

Termination points have their own temperature ratings. If the termination ratings are different than conductor ratings, then you must use the lower of the two ratings. For instance, if a conductor is rated for 75oC, but the terminations are only rated for 60oC, you must use the 60oC rating in your calculations. Alternately, if the termination is rated for 75oC, but the conductor is only rated for 60oC, you still must use the 60oC rating when calculating permitted conductor ampacities in Table 310.15(B)(16).

The Number of Conductors in Conduit: Adjustment Factor

When four or more conductors are placed in the same conduit, they cannot dissipate heat as quickly as three or fewer conductors. In these situations, conductors are limited to less ampacity because of the extra heat in the conduit. Reduction of ampacity due to the number of conductors in a conduit is referred to as an adjustment factor. When conduit contains four or more conductors, the total ampacity must be reduced by the percentages listed in Table 310.15(B)(3)(a).

Ambient Temperature: Correction Factor

The ambient air temperature around a conductor also affects permitted ampacities. Colder temperatures allow conductors to safely handle higher ampacities. Hotter temperatures reduce permitted ampacities. Ampacity changes due to ambient temperature are called correction factors. Standard air temperature is between 78oF and 86oF according to the 2017 NEC. When ambient temperature is below 78oF or higher than 86oF, then the conductor ampacity must be corrected based on the percentages listed in Table 310.15(B)(2)(a).

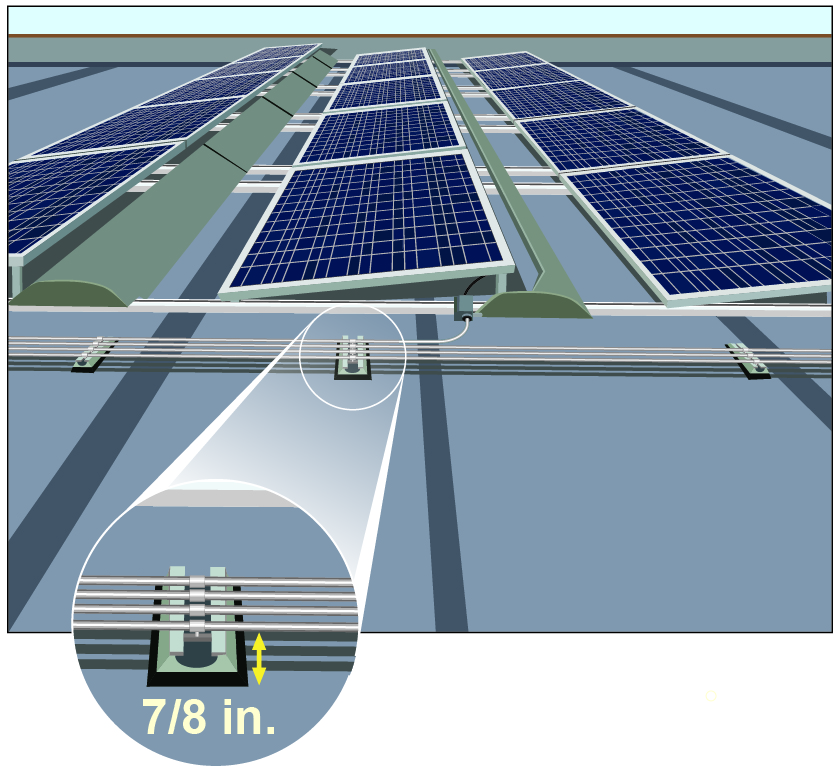

Conduit Level Above the Roof

Conduit position above the roof is tremendously important in calculating rooftop conductor ampacity. According to 310.15(B)(3)(c), if the top of the roof to the bottom of the conduit is less than 7/8”, then an additional 60oF must be added to the ambient temperature correction described above. So, if the ambient temperature of a roof is 95oF, and the conduit is less than 7/8” from the top of the roof, you would need to recalculate the ambient temperature to (95oF + 60oF=) 155oF! At first the correction may seem too high. But, if you imagine the wire cooking in conduit that is very close to the roof, you may realize this correction is necessary for the protection of the conductor insulation.

An Exception for Type XHHW-2

According to the exception in 310.15(B)(3)(c), Type XHHW-2 conductors can be used without adding the additional 60oF correction factor, even if the conduit is less than 7/8” from the top of the roof.

Example

How would the 60oF temperature addition affect the ampacity of a conductor if one conduit was 7/8” from the top of the roof and another was less than 7/8”?

In this example, 1/0 copper THHN wire will be used. The terminal temperature rating of the equipment is 75oC. There will be three conductors in the conduit. The ambient temperature is 85oF.

| Conduit is placed 7/8″ or higher above the roof | Conduit is placed less than 7/8 ” above the roof | |

| Step 1 | 150 Amps | 150 Amps |

| Step 2 | 150 Amps | 150 Amps |

| Step 3 | 150 Amps | 70.5 Amps |

Step 1. Use Table 310.15(B)(16) to provide the starting ampacity of 1/0 copper THHN wire. Since the terminations on the equipment are only rated for 75oC, the conductor ampacity rating must be from the 75oC column, rather than the 90oC column for THHN. The 75oC column rates 1/0 copper at 150 amps at standard ambient temperature.

Step 2. Determine if there is an adjustment factor due to the number of conductors in the conduit. Only three conductors are in the conduit, so no adjustment factor is needed.

Step 3. Determine the correction factor. The ambient temperature in this example is 85oF, which is within the standard ambient temperature range. If the conduit is placed at 7/8” above the rooftop, the conductor does not need corrected per Section 310.15(B)(3)(c). However, if the conduit is lower than 7/8” to the rooftop, then 60oF must be added to the ambient temperature correction factor. The ambient temperature of 85oF is added to 60oF, which equals 145oF. Table 310.15(B)(2)(a) requires a 0.47 ambient temperature correction in the 75oC column for 145oF. 150 amps times 0.47 equals 70.5 amps. The reduction in permitted ampacity is over half in this example because of the proximity of the conduit to the roof.

Proper Planning Leads to Money Savings

Due to the massive ambient temperature addition in Section 310.15(B)(3)(c) of the 2017 NEC, installing conduit less than 7/8” above a roof could lead to a huge loss in money; conductor size will need to be increased in order to compensate for the loss of permitted ampacity. By simply planning to raise the conduit to 7/8” above the roof, the ambient temperature addition is no longer required, so larger conductors are no longer needed. By using Type XHHW-2 conductors, the large rooftop ambient temperature addition can also be avoided.

Do you apply the average high ambient temperatures for your location found in the ASHRAE Handbook — Fundamentals on Raceways and Cables installed outside or on the rooftoo?

The simple issue of sunlight resistant conductor types is a maze. No where I’ve found lists the wire types that are “sunlight resistant” according to the NEC