2020 National Electrical Code: Article 330 Metal-Clad Cable Type MC

By: Dave Varga | Mar 25, 2021

Metal-Clad (MC) Cable is used every day in the electrical industry. The true conduit benders hate it. The value engineering people love it. MC Cable is really a great product, has a wide variety of uses, and can be installed to look good. Let’s take a closer look at this industry workhorse: Metal-Clad Cable.

MC Cable Definition

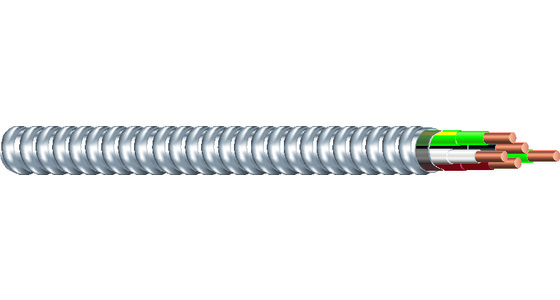

MC Cable, by most common definition, is a factory assembly of one or more insulated circuit conductors enclosed in an armor of interlocking metal tape or a smooth or corrugated metal sheath. The smaller cables should be unsheathed by using an armored cutter like the famous “Roto-Split”. The fittings must be listed and identified for use. If the manufacturer provides anti-short bushings, they can be used. The bushings are not an NEC requirement since the listed MC connectors provide the conductor protection from sharp edges.

MC Cable Permitted Uses

The permitted uses for MC Cable can be found in Article 330.10(A) 1 – 12. MC Cable, when listed and labeled for use, can be a wiring method in locations such as:

- Commercial, industrial, and residential/commercial buildings

- Environmental Air Plenums, Article 300.22

- Hazardous Locations, Article 500

- Health Care Facilities, Article 517

- Places of Assembly, Article 518

- Theaters, Article 520

- Under raised floors for Information Technology equipment, Article 645

- Power and lighting control (dimming), Article 725

Worth mentioning is new Article 330.130 Hazardous (Classified) Locations in the 2020 NEC. This article allows cable installation, where required to be marked MC-HL cable, in hazardous locations. MC-HL cable has a gas/vapor tight continuous corrugated metallic sheath, an overall jacket of suitable polymeric material, and the typical separate grounding conductor.

MC Cable Sizes

In general, MC Cable comes in a variety of sheathings, lengths, conductor sizes (ampacities), and even copper or aluminum conductors. The sizes of MC Cable range incredibly from 14 AWG to 1000 kcmil.

MC Cable Benefits

Using MC Cable can save a lot of valuable labor hours versus the installation of conduit. In fact, MC cable reduces overall installed costs by roughly 30-50% when compared to the installation of conduit and wire. The cable can be used quickly from small 250’ rolls or even much larger 1000’ spools of cable. Supporting the cable, as described in Article 330.30, is basically every 6’ and 12” before each box.

A run of conduit is limited to 360 degrees whereas MC cable has an unlimited number of bends. MC cable can fit quickly into many places and tight framing spots. The only limit to a typical corrugated sheathed MC Cable installation is the bending radius as seen in Article 330.24 (B). The radius of the inner edge of the curve must not be less than seven times the outside cable diameter.

Above the ceiling, small MC cable can be unsupported in lengths up to 6’ as allowed in Article 330.30 (D)(2), luminaire connection. Article 330.30(D)(3) allows cable to be unsupported for up to 3’ where it is connected to equipment and needed to be flexible and to minimize the transmission of vibration. MC Cable can even be grouped together; see Article 310.15(C)(1)(d) and the exception. Also new to the 2020 NEC is Article 330.80(C) Thermal Insulation. This article addresses MC Cable installed in contact with thermal insulation, caulk, or sealing foam and refers us to adjustment factors as found in Table 310.15(C)(1).

Conclusion

Overall MC Cable has a lot of capabilities (services, feeders, branch circuits), can be used in many locations (assembly, hazardous, plenums), and can save time and money (30-50% over conduit and wire). An MC Cable installation can be neat and orderly when installed per Article 110.12. All of these reasons contribute to why Metal-Clad Cable is used so often in the electrical industry.

As a building facilities guy. MC has it’s place. We have a couple of buildings on campus that we have allowed MC one is a office building and one is a laboratory building. The office building it has not been so bad. The Laboratory building has been a ABSOLUTE nightmare for us. The contractor did pre-fab on most of the panels in the labs. Which consists of Panelboard with 2″ EMT stubbed into a large J-box with a stab in terminal block mounted in it. When you load up these circuits, we have had a few failures on said terminal Blocks. from these j-boxes the MC cables spider web out to to various places in the labs they service. Some runs can be as long as 100 feet. These locations usually have a piece of equipment, that change quite frequently. A lot of times it is easier and less time for my guys to just replace wire and device.

We have recently rewritten our spec’s to make it a kind of hybrid. Where There are home run conduits out to different quadrants. Then MC Cable down into walls, or any fixture that is farther than 6feet ( factory assembled fixture whip.)

Can I get a soft back copy of the 2020 NEC?

My 2020 NEC book is paperback.

Does anyone know if MC cable can be used in private homes in New York City?

Is there anywhere that states that MC cannot be used as a circuit for 50 amp welder plugs as long as I’m not over 100′?