3-Wire Cords on Modern 4-Wire Appliances

By: Jerry Durham | Sep 18, 2018

NEC 2017 250.140 (Exception)

In an existing installation (such as an older home built in the 1950s), it is considered Code-compliant for the kitchen range or the clothes dryer to be installed using a 3-wire cord and plug. However, in new construction the installation of kitchen ranges and clothes dryers requires a 4-wire cord and plug. The 4th wire in that cord and plug configuration is an equipment grounding conductor. This equipment grounding conductor is the missing wire in the older 3-wire configurations.

In these older appliance installations where 3-wire cords were legally installed, the wiring consisted of two hot wires and a neutral wire. The two hot wires provided both phases, which were 180 degrees out of phase from one another, to handle the big electrical load of the range or the dryer, and then the neutral wire which acted as a return path for any 120-Volt loads incorporated into that 240-Volt range or dryer, such as the built-in light or timer. (Note: These small loads that are a part of kitchen ranges and clothes dryers, such as clocks, timers, lights, LED displays and similar, are usually 120 Volts, even on ranges and dryers that are 240 Volt. As such, they require a return path for that 120 Volt current in the form of a neutral.)

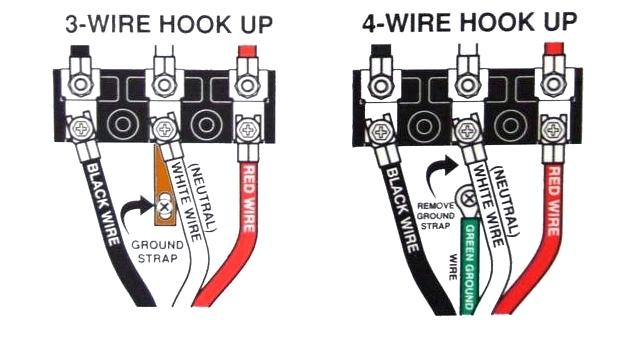

In the older style 3-wire cord and plug setup, the neutral did two jobs: (1) it carried the return current back to the source for the aforementioned 120 Volt appliance loads, and, (2) it was connected to the metal frame and metal housing of that same appliance, so that in the case of a short to ground condition, the circuit-breaker at the panel would trip. If the Neutral in that 3-wire configuration wasn’t connected to the metal frame and housing of the appliance, the circuit-breaker protecting the appliance would not trip during a short to ground condition. For example: if a hot wire within a clothes dryer broke loose from the heater element due to vibration, and then made contact with the metal housing of the dryer, that metal housing would become energized and would remain energized indefinitely, as long as there was no path for that shorted current to travel to get back to its source. This energized metal would then no doubt shock someone who came into contact with it, if they were grounded; such as a person with bare feet on a basement floor. The takeaway from this is that without a return path for current to flow, that is connected to the exposed metal of an appliance, applied voltage to that metal during any kind of fault condition would just remain on that metal. That is why even in the 3-wire cord configuration, a return path in the form of the neutral wire was attached to the exposed metal.

In the 4-wire cord and plug configuration, the equipment grounding conductor now serves to do one of the jobs that the neutral was doing previously in the old 3-wire setup. The equipment grounding conductor is now the conductor that is attached to the metal frame and housing of the appliance. It has the sole responsibility of carrying back any fault current on that metal during a short to ground condition. The neutral in that cord is no longer connected to the metal frame and housing, and indeed cannot be, as it is prohibited by the NEC during new construction.

The reason the neutral wire of an appliance is no longer permitted to carry fault current back to the source, (which means it can no longer be attached to the metal frame and housing of an appliance), is because it was determined long ago that attaching the exposed metal of an appliance to a neutral conductor that is carrying current is a bad idea. That moving current is always looking for the path of least resistance back to its source, and under the right circumstances, such as a homeowner standing barefoot on a wet basement floor, that current on the exposed metal of that appliance may just briefly decide that a human being in contact with that exposed metal is that path of least resistance. Explore our electrical license exam prep courses now.

Excellent article! I get many questions from homeowners about this. I’m saving this so as to better explain the differences as well as the reasons why.

Thanks!

Back at the panel, aren’t there only 3 places to put these wires – the two hot legs and the ground. Do the neutrals and the grounds go to the same place? If so they are still connected togather in the panel. Is this right?

Finally explained correctly.

Although I always understood the reason for a 4 wire installation, I didn’t understand how you might get shocked with a 3 wire system. Bare feet in water in the basement causing a shock makes sense.

My stove has 4 wire hook up but the wall outlet is a 3 so how can I hook it up to the 3 plug

another thing, if a neutral wire somehow gets disconnected, it becomes part of the hot, and with it touching the surrounding metal, it will feed voltage in to it and you would get shocked touching it.

Why is there no grounding strap on my 3 wire connection on my dryer?

If the appliance is entirely 220v then the 3rd conductor should be ground.

Old 220 v receptacle has 3 prong plug. Newer replacement dryer has 4 prong plug. Can I just switch cords using the old 3 prong to fit my outlet?

Hello can I hook up new electric stove using 4 prong cord to old 3 wire coming out of wall?

How do I put a new ground strap on a kenmore stove. I purchased a used Kenmore stove that has 4 prong chord but I have a 3 wire set up in my house the previous owner of the stove removed the ground strap. I know I need a ground strap to convert back to 3. How do I put a ground strap back on correctly

Hi Casey,

I don’t know if you solved your dilemma yet. But there is no right way to do this beyond what the manufacturer provided in the beginning. I suspect there are inexpensive kits online for restoring the ground strap on an appliance where it has been removed, but you will need to install the kit in the manner the original strap was installed or how a listed/approved strap kit recommends. Most people are removing these straps from appliances, versus installing them. But I suspect a kit is available. It is important to note: Without that strap, assuming you are plugging a 4-wire appliance into a 3-wire receptacle, you will be without an equipment ground on the appliance. Meaning if an ungrounded (hot) conductor comes loose or is chaffed (the wire’s insulation) inside the appliance and touches exposed bare metal inside the appliance, it will energize all bare metal without ever tripping a breaker. The outside of your appliance, in this case, becomes an energized conductor.

Best,

Jerry – JADE Learning Instructor

A small piece of 12awg wire will do the trick. Just put one end under the neutral and the other under where the old strap was. Should be just below, or above the terminal block on the metal frame of the unit.

Hi,

Is it safe to use an adapter plug, I see them for sale online? I have a new induction stove with a four prong plug that needs to go into an older three prong on the wall, the cord on the stove is not removable, so I’ve been told.

How about installing a 4 prong receptacle and make it all safe the way it should be by removing the 3 prong plug and using the available abandoned ground wire in the box ?

While it is true that the two LEGS in a residential 120/240 electric service are out of phase with each other by 180 degrees (and many laymen as well as professionals sometimes refer to them as phases), the industry does not technically recognize them as phases. Instead they are known as two legs of a single phase. The industry defines that two phase system as having two voltages 90° out of phase.

Does anyone make a 3-wire:4-wire receptacle adapter? I have a 3-wire outlet and a 4-wire dryer appliance.

This article provides valuable insights into the importance of electrical safety when dealing with modern appliances. As technology evolves, so do safety standards, and it’s crucial to keep up with these changes. The explanation of the differences between 3-wire and 4-wire cords and the potential risks associated with older 3-wire setups is enlightening. It emphasizes the significance of following updated guidelines and regulations to ensure the safety of both people and property. Electrical safety is a topic that affects us all, and this article serves as a reminder of the importance of staying informed and making the necessary updates to our electrical systems.

It would seem to me that running a separate bare ground wire along with the SE aluminum 3 wire cable & terminating it grounded in the main service panel & connecting it to an equipment ground inside the appliance receptacle would solve the conundrum without pulling in a new 4 wire appliance cable.

Is there a way to safely connect a 240V iron with G type plug to a 4 wire dryer outlet? Already have a matching G type receptical but not sure about how to wire it. The type G receptacle’s 3 connections are labeled L, N and G.

Thanks.