Duct Material Comparison for Residential Installations

By: Reggie Hucks | Sep 26, 2019

When homeowners receive quotes from HVAC contractors, they typically are given two duct replacement options: sheet metal or fiberglass duct board. There is a third option, phenolic duct, that is made of plastic foam with a foil liner on the inside and exterior. It hasn’t been on the market long enough to weigh in on its merits and shortcomings and will not be included in this comparison. Homeowners usually go for the product their HVAC contractor recommends; however, all systems have their strengths and weaknesses. Here are the advantages and disadvantages of two of these materials when installed in the typical residence.

Sheet Metal

Let’s start with sheet metal since it has been around longer. Sheet metal, made of galvanized steel or aluminum, is fabricated into round or rectangular duct for transporting air. When properly installed, sheet metal systems are robust and can provide many years of service. Air moves easily in metal duct systems with less friction loss. Expensive machinery is required to fabricate the sheet metal ductwork; therefore, fabrication costs are more. Where the material is fastened together, care must be taken to tightly seal the joint to prevent energy loss. Listed tapes or mastics are used to seal the metal.

Metal systems must be insulated in unconditioned spaces for energy efficiency and to prevent condensation. Insulation is placed on the interior or exterior of metal duct. When wrapping the duct exterior, staples and tapes are used to secure the insulation. The wrap shouldn’t be pulled too tightly or a loss in the insulation effectiveness will occur. Placing insulation on the interior means cutting the insulation to fit and fastening the material in place.

One health benefit of metal duct is that it doesn’t expose the system’s airflow to fiberglass if externally insulated. When insulation is installed on the duct’s interior, building occupants are exposed to fiber particulates from the airflow. In some parts of the country, the use of fiberglass insulation in the air stream includes health hazard warning statements. Therefore, the contractor can choose external insulation for most installations.

Duct Board

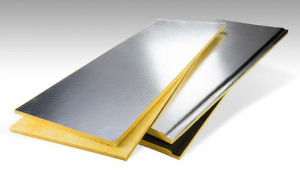

Duct board is a second option that contractor’s frequently offer. This material has been around for fifty years or more and is basically large sheets of rigid fiberglass insulation with an attached foil vapor barrier. It has several advantages over metal installations that contractors prefer. It produces very little air noise when under pressure. Fabrication is faster and less labor intensive. Special knives cut the duct into square or rectangular shapes as needed, therefore, expensive machinery is not required. The material is also easy to seal air tight.

Duct board installations have a few drawbacks too. Because duct board consists of rigid insulation, fibrous material can erode into the airstream. It should be noted that duct board can be bought with a treated surface that resists erosion. The treated duct board can be harder to fabricate than the untreated variety and costs more to install.

Water and duct board do not play well together. Wet duct board can produce mildew and encourage mold growth. Mold needs an organic food source, low light levels, and water to thrive. Installing duct board in areas such as a wet crawlspace creates an environment that mold needs to start growing. Basically, the fiberglass absorbs moisture and provides a breeding ground for mold spores. Therefore, duct board should only be used where it will not be exposed to damp conditions.

The winner is…

Both systems have been used for years and, when installed appropriately, will give good service. Overall, the edge probably goes to professionally installed metal systems that are externally insulated. Potential health hazards are lower, and a longer service life can be expected.

It’s good to know that if your air duct is made of sheet metal and well insulated then it won’t be exposed to fiberglass. I can only imagine how horrible and unhealthy that would be. If I get a new HVAC system in my house I’ll ask the contractor if they think that a sheet metal one will be better or not.

Thank you so much for sharing such a nice information related to Air Duct and HVAC system.

An HVAC “specialist” said they wanted to install “plastic ducts” – What is a plastic duct please?

And what are the pros, cons, and your thoughts on “plastic ducts” versus others?

Thanks in advance 🙂