Grounding Versus Bonding: Part 1

By: Jerry Durham | Jun 15, 2018

By: Jerry Durham, JADE Learning.

The terms Grounding and Bonding are found throughout the NEC text, and while they are seemingly interchangeable, they are actually two distinct procedures when it comes to the National Electrical Code and installing electrical equipment.

The act of “grounding” (versus bonding) is so important, in fact, that the NEC Code-Making-Panel (CMP) had actually proposed to replace the term “grounding” altogether, so as to provide a term that offered better clarification. Their proposal at that time was to replace the word grounding with “earthing.” This proposed change to the NEC gained a lot of traction, but before the Code’s publication, the proposal was ultimately retracted.

Grounding

What is grounding exactly? Let’s use what we have learned to deduce the answer.

Knowing that the NEC Code-Making-Panel was considering replacing this term with the word “earthing” gives us a good indication of just what the term is trying to relay to us: to wit, “grounding” means to provide a conductive path between electrical equipment and the earth. We can now see why the term “earthing” nearly won the tug-of-war of terms!

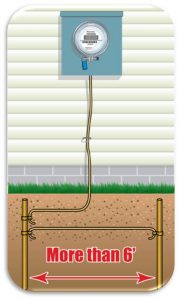

Let’s look at an example of grounding

An electrical panel is installed outside of a dwelling unit and there is a copper ground rod driven into the earth below. There is a bare, solid copper No. 6 conductor attached to a lug within this electrical panel, and the other end of that No. 6 conductor is clamped onto the driven rod. This is an example of grounding. We have grounded this metal electrical panel by connecting it to the earth!

Bonding

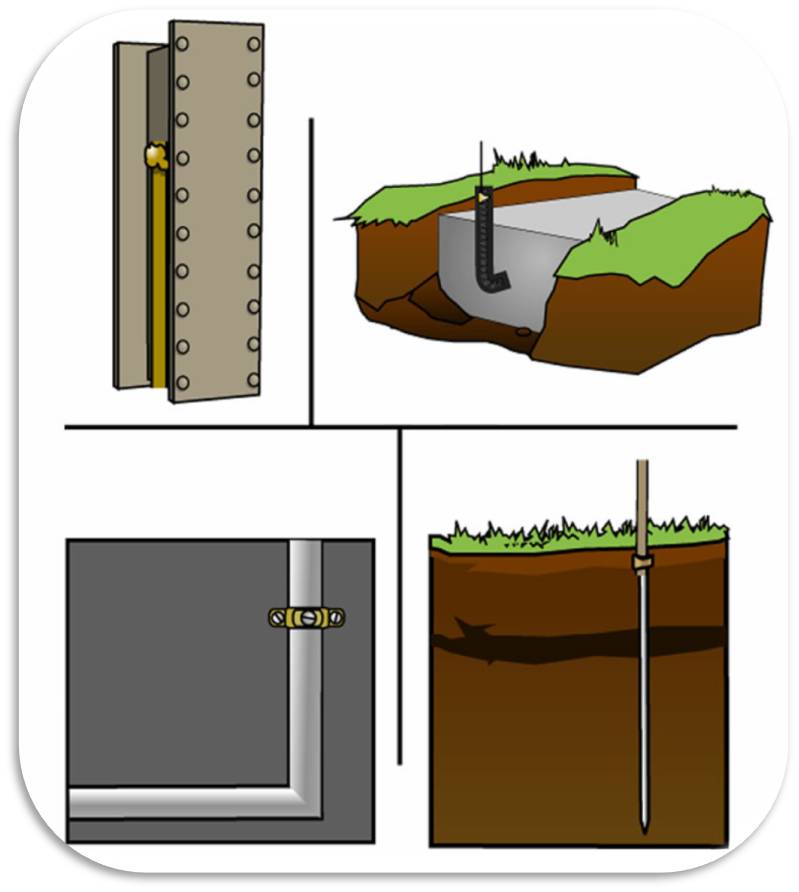

What is bonding? Bonding is simply the act of mechanically connecting two or more conductive materials together to establish a conductive path between them. It is possible to “bond” components together without ever grounding them.

Let’s look at this real-world example of bonding

Let’s suppose I have three metal, 4-square junction boxes mounted on a non-conductive wooden wall, the boxes are spaced 10’ apart. After finding out that we are completely out of EMT (metal thin-wall) conduit on the jobsite, I decide to install a 10’ piece of PVC (plastic) conduit between the three metal boxes so that I can complete the job today. I then recall that my employer had specifically told me to bond all 4-square metal junction boxes together in this building. Initially, that was being accomplished by using EMT (metal) conduit between the metal boxes. But I have changed the material to plastic PVC conduit between these last three boxes.

We are aware that the PVC pipe that we have just installed, being essentially plastic, is not a conductor and therefore cannot serve to “bond” these three metal 4-square boxes together. But, if we run a green-colored insulated conductor between the three boxes, utilizing the PVC conduit as a raceway, and then attaching the conductor to the inside wall of each metal box with an approved green bonding screw, we have then successfully “bonded” these three metal boxes together. All of the metal boxes are now bonded together on this job.

So far, so good!

Bonding Vs. Grounding

But alas, we find during a closer inspection that we have left out one critical step in our installation. Though we have successfully bonded these three metal boxes together by connecting them with the green-colored insulated conductor, we have not yet installed a conductor connecting the three metal boxes to the grounded electrical panel. In other words, all of the boxes are connected to one another, but as a system, they are just “floating” – we have not yet introduced a path for fault current to flow from the metal boxes back to the electrical panel! A circuit breaker could not trip during a ground fault condition without that essential path for fault current to flow.

Understanding that dilemma is the point of this article. We want to help you understand that to “bond” components together, is not to ground them. The two terms are in no way interchangeable, and the life-saving benefits gained by grounding equipment are not replicated by merely bonding the equipment. These are two distinct procedures and both are essential when installing metal electrical enclosures, boxes, and equipment within any electrical system.

Part 2 of Grounding VS. Bonding is now available on this website!

Learn More

To learn more about grounding and bonding, sign up for a JADE Learning electrical continuing education course.

All these years in the field we’ve been using a floating system. This was intriguing to learn the distinction between grounding and bonding. Thanks!

I am an Electrical Engineer and teach electrical classes occasionally,that is such an accurate and understandable explanation,I will use it in my classes,great job; Larry Strunk e.e.

great info but is bonding the enclosures ( J boxes ) better than using grounding bushings?

Isaac;

Thanks for your question – we will shortly be answering it with a more in depth article on our website. Check back in the next week or so.

Excellent and that is the way to explain it grounded path save lives.

Great job on explaining the difference.

Grounding is not for fault current. NEC states that earth is NOT an acceptable path for fault current. The bond to neutral is the required path for fault current.

Thank you for your comments!

You are absolutely correct. Details regarding how fault current returns to the voltage source, for the sake of triggering the OCPD, is better covered in the upcoming parts of this Grounding and Bonding article. With that said, I kept that information to a minimum, as it was my goal to keep this lesson on point, and as simple as possible. The difference between grounding and bonding eludes many, any additional elements to the material can take away from the simple differences we are trying to convey.

Coming posts will address this in more detail! I also have a piece on the difference between Arc fault and Ground Fault protection- how the Solid-State components work- the oscilloscope effect, and general theory. I’m hoping to get that one out sometime soon. Hope you will join us for those as well!

Thanks

Jerry Durham

Instructor

Very good way to explain the difference to the newer or upcoming electricians. Grounding can get really confusing.

Fantastic! I am also an Electric Engineer (BSEE) and Hispanic. In Spanish we have always use the word “Aterramiento”, what will be “earthing” as you clearly explained here. Aterramiento means ‘to take to ground’ (“Llevar a Tierra”). Keeping this in mind, the whole thing boils down to providing all the elements of an electrical installation a “common ground” to avoid voltaje differentials that could result in a pathway to take a shortcut through some human body handling any part of the design. Your explanation has ended the confusion that was created in my mind when I was introduced to the term ‘bonding’ in the USA.

I’m Electrical Enginer and the concept of a grounding and bonding is very important for the security of people.and equipment in al type of building, residential, commercial and industrial as well….