OSHA and the Electrician

By: Wes Gubitz | Jan 09, 2019

What are your responsibilities concerning meeting the requirements set by the Occupational Safety and Health Administration (OSHA)?

The Occupational Safety and Health Act of 1970 was put into law and Congress created the Occupational Safety and Health Administration (OSHA) to assure safe and healthful working conditions for working men and women by setting and enforcing standards and by providing training, outreach, education and assistance. Under the OSH Act, employers have a responsibility to provide a safe workplace.

Working with electricity can be dangerous. Engineers, electricians, and other professionals work with electricity directly. This includes working on overhead lines, industrial motorized equipment, cable harnesses, and circuit assemblies. Others, such as machine operators, office workers, and sales people work with electricity indirectly and may also be exposed to electrical hazards.

Electricity has long been recognized as a serious workplace hazard. OSHA’s electrical standards are designed to protect employees exposed to dangers such as electric shock, electrocution, fires, and explosions.

The good news for the employee is that you have been meeting your areas of responsibility to your employer and yourself if you have correctly applied the National Electrical Code, standard 70, and Electrical Safe Work Practices, standard 70E, published by the National Fire Prevention Association (NFPA). These safety standards are considered industry consensus standards used by OSHA as acceptable and enforceable safety standards for the workplace.

Originally developed at OSHA’s request, the NFPA 70E helps companies and employees avoid workplace injuries and fatalities due to shock, electrocution, arc flash and arc blast, and assists in complying with OSHA 1910 Subpart S and OSHA 1926 Subpart K. The electrician will, for the most part, meet their specific trade responsibilities to their employer and OSHA by compliance with the NFPA 70 and 70E. They will have additional responsibilities that apply to all trades, both in the Construction Industry and in General Industry.

Most employees are familiar with the 10-30 hour OSHA Training that covers safety training for their work place. This training should be supplemented with additional training topics and retraining as/when needed throughout the year. The employer has the ultimate responsibility of assuring a safe and healthful workplace for all of their employees. I remember my first exposure to the management/administrative side of OSHA in the workplace. It happened within a few weeks of my signing on as a plant electrician with a sawmill in northeast North Carolina.

I was not there long before we had an on-sight OSHA inspection. Within minutes of their arrival, I was reassigned to the Safety Coordinator to help out as he accompanied the OSHA Team on their inspection tour. The inspection started at the written programs, then to the shops, the kiln, then on to the production and storage areas. They were on-sight for a week. All in all, we did well, and I had the opportunity to receive a crash course on what is expected on the administrative side of meeting OSHA Standards and Regulations in the field.

Managing the administration of OSHA Standards and Regulations can be a full-time job pending on the size of the workforce and the type of industry, and this is the best-case scenario. A worst-case scenario is when you have to take it on as a part-time do as you can responsibility; this is when it can become overwhelming, even impossible. OSHA has a very exhaustive website available for assisting the employer in meeting their responsibilities. www.osha.gov will direct you to a list of management and administrative helps at the end of this article to help the part-timer.

I would normally encourage my students to take some time to explore a website while looking for topics that might be of interest to them, but for this exercise, I want to be more direct in my approach. Go to the OSHA home page, www.osha.gov. Click on the searchable “A to Z Index,” located in the top right corner of the page in the red ribbon just below the search box. See Fig. 1.

Fig. 1

Scroll through the alphabetical list to find and select “Electrical”. (See Fig. 2). This action will take you to another page that provides information specific to the electrical profession (see Fig. 3).

Fig. 2

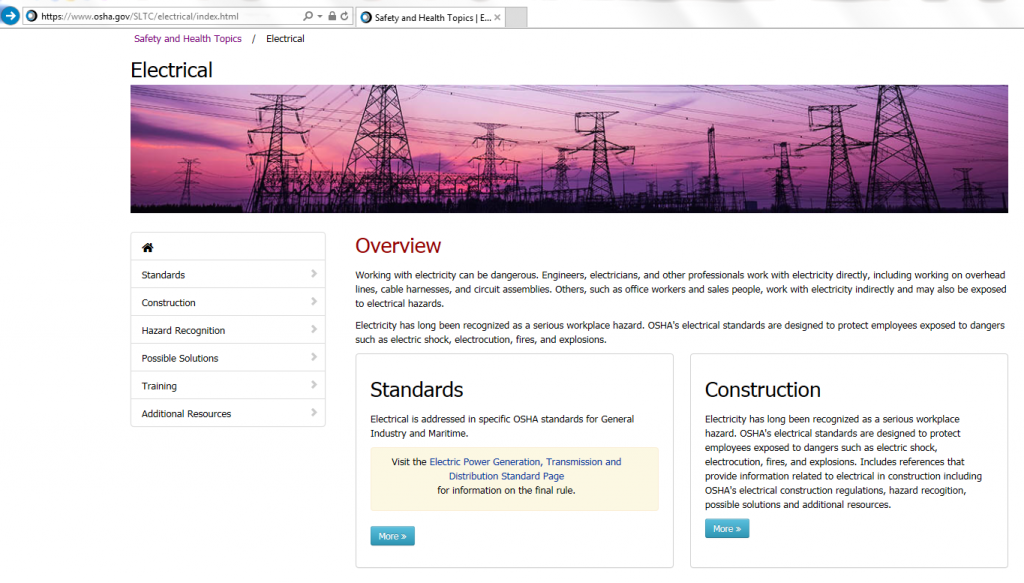

This page is the Electrical portal that allows access to most of the information you will need to assure you provide a safe and healthful workplace for your electrical employees.

Fig. 3

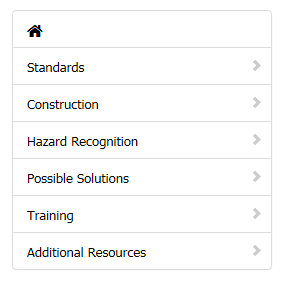

A menu provides short cuts to specific topics; these topics are also shown in the text boxes with brief descriptions of what each page contains. (See Fig. 4).

Fig. 4

Let’s take a look at what OSHA Standards apply to the electrician. Select “Standards,” or right click on “Standards” and open in a new tab. This section highlights OSHA standards, Federal Register notices (rules and proposed rules), directives (instruction to OSHA staff), and letters of interpretation (official letters of interpretation of the standards) and national consensus standards related to electrical hazards.

The General Industry Standards, 29 CFR 1910 Subpart S – Electrical, can be a bit daunting and too much to consider this late into the article. I encourage you to revisit this topic at a later date, before you have the need to, and when you have some time to invest. Let’s close this article after reviewing menu item “Hazard Recognition.” Click on “Hazard Recognition.”

Page overview: “Many workers are unaware of the potential electrical hazards present in their work environment, which makes them more vulnerable to the danger of electrocution. The following hazards are the most frequent causes of electrical injuries: Contact with Power Lines, Lack of Ground-fault Protection, Path to Ground Missing or Discontinuous, Equipment Not Used in Manner Prescribed, and Improper Use of Extension and Flexible Cords. [29 CFR 1926.416(a)(1)]

There are several specific links available at the bottom of the Hazard Recognition page. I have selected one for the electrician and one for the manager. The first is a free eBook for the electrical student. Much of this material is basic, but necessary. Next is a booklet that provides samples of written programs; a good place to start. Electrical Safety-Safety and Health for the Electrical Trades https://www.cdc.gov/niosh/docs/2009-113/pdfs/2009-113.pdf?id=10.26616/NIOSHPUB2009113

Samples of Written OSHA Programs: https://www.osha.gov/dcsp/compliance_assistance/sampleprograms.html

What year was the Occupational Safety and Health Act put into Law?

1970

I like how you said that the employees should go through retraining as necessary so that they are staying safe and educated. My cousin works in construction and he says that he gets trained frequently so that they can minimize workplace accidents. I think that’s really smart because the more prepared you are, the less likely you are to make a mistake.