2018 NFPA 70E Update: The Language of Electrical Safety

By: Dennis Bordeaux | Feb 12, 2018

By: Dennis Bordeaux

The 2018 edition of NFPA 70E: Standard for Electrical Safety in the Workplace contains many changes, text has been revised, some requirements have been relocated or deleted, and new material has been added. The common point of all changes is to make the standard easier for both employers and employees to understand and apply in the workplace.

For example, Section 105.3 has been revised to separate the employer and employee responsibilities into separate paragraphs. The changes make it clear that electrical safety in the workplace is the result of a partnership between employer and employee. Both must do their part.

Employer

The employer has two main responsibilities under 105.3.

- Establish, document, and implement the safety-related work practices and procedures required by NFPA 70E.

- Provide the employee with the necessary training to understand and apply those safety-related work practices and procedures.

Employee

The employee has only one stated responsibility:

- Follow the safety-related work practices and procedures provided by the employer. It sounds simple, but following the documented safety-related work practices and procedures requires not only awareness of what to do and why, but also the self-discipline to follow those procedures when no one is looking.

An understanding of the technical terms used in the standard is fundamental for both employers and employees in developing and following electrical safety-related work practices. These terms establish a common language of electrical safety for employers and employees.

Definitions for terms used in two or more articles of NFPA 70E are found in Article 100. The 2018 edition includes several new and many revised definitions that are necessary to the proper application of NFPA 70E requirements, including for the first time, a definition for what an Electrical Safety Program is:

Electrical Safety Program. A documented system consisting of electrical safety principals, policies, procedures, and processes that directs activities appropriate for the risk associated with electrical hazards.

It is important to emphasize that the electrical program is a documented system of integrated components that work together, not just a collection of miscellaneous safety-topics in a 3-ring binder that never gets looked at.

Electrical safety principals are the foundation of an electrical safety program and should be documented as the stated principles will guide the policies, procedures, and processes that are developed to manage the risk associated with electrical hazards. For example, a statement such as “All work tasks that expose an employee to an electrical hazard shall be planned in advance,” makes it clear what the employer expects. Specific requirements as to what should be included in job safety planning are found in a new section: 101.1(I). Another core principle that should be included in the electrical safety program is the inspection and maintenance of electrical equipment.

Electrical equipment that is installed in accordance with the NEC and manufacturer’s installation instructions and properly maintained can be expected to perform as intended, but who verifies the installation is in compliance with the applicable codes and installation standards prior to placing the equipment in service?

Inspection of electrical equipment is addressed in 2018 NFPA 70E new Section 110.1(B):

Inspection of electrical equipment is addressed in 2018 NFPA 70E new Section 110.1(B):

Inspection. The electrical safety program shall include elements to verify that newly installed or modified electrical equipment or systems have been inspected to comply with applicable installation codes and standards prior to being placed in service.

Although a local electrical inspector may inspect the basic wiring system within a building for compliance with the NEC, in an industrial location it will often fall to the owner/employer to provide a process for verifying that electrical equipment and associated wiring has been installed in compliance with the applicable system design and installation requirements.

Even equipment that has been correctly installed must be properly maintained. Poorly maintained equipment may expose equipment operators or maintenance personnel to electrical hazards. Section 110.1(C) has been revised to clarify that the electrical safety program must include elements that consider the condition of maintenance of the electrical equipment and electrical system.

A new definition for condition of maintenance has been added in 2018 NFPA 70E Article 100:

A new definition for condition of maintenance has been added in 2018 NFPA 70E Article 100:

Maintenance, Condition of. The state of the electrical equipment considering the manufacturers’ instructions, manufacturer’s recommendations, and applicable industry codes, standards, and recommended practices.

The basic safety principle is clear. Poorly maintained electrical equipment, just like a poorly maintained automobile, is not likely to perform as originally designed. It is more likely to pose an electrical hazard to an equipment operator or maintenance technician.

The definition of electrical hazard in Article 100 has been revised to include arc blast injury as one of the possible hazards.

Electrical Hazard. A dangerous condition such that contact or equipment failure can result in electric shock, arc flash burn, thermal burn, or arc blast injury.

Additional information on the types of injuries associated with electrical hazards is found in a revised Informative Annex K. Informative annexes do not contain mandatory requirements, but they can help us understand and apply the requirements of the standard.

For practical purposes, the safety-related work practices in 2018 NFPA 70E address the two major hazards of electric shock and arc flash. If we can eliminate the chances of an electric shock or arc flash occurring, an electrical incident will not result in injuries. A new Section 105.4 requires hazard elimination to be the first priority when implementing safety-related work practices.

Where it is impossible to eliminate the risk of electric shock or arc flash, following safety-related work practices, procedures, and processes documented in the electrical safety program will reduce the risk of injury to an acceptable level.

Identifying the electrical hazards associated with a task is the responsibility of the qualified person in charge of the work. The job safety plan must include a shock risk assessment for work involving shock hazards and an arc flash risk assessment if an arc flash hazard is present.

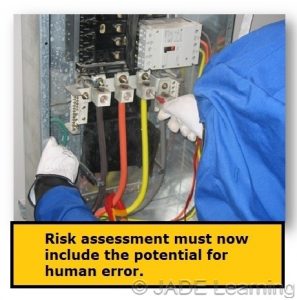

Risk is a combination of factors that takes into account the likelihood that an electrical incident resulting in an injury will occur (probability) and the severity of the injury that may result (consequences) if the incident occurs. In order to know what risks are associated with a particular electrical task, a risk assessment must be performed by a qualified person prior to beginning the work. The definition of risk assessment has also been revised.

Risk Assessment. An overall process that identifies hazards, estimates the likelihood of occurrence of injury or damage to health, estimates the potential severity of injury or damage to health, and determines if protective measures are required.

Risk Assessment. An overall process that identifies hazards, estimates the likelihood of occurrence of injury or damage to health, estimates the potential severity of injury or damage to health, and determines if protective measures are required.

Specific requirements for risk assessment procedures are covered in 110.1(H). This section has been significantly revised. Risk assessment procedures must now specifically address the potential for human error. The hierarchy of risk control methods which was included as a nonmandatory informational note in the previous edition of NFPA 70E is now included in 110.1(H). The most effective risk control method listed is elimination of the hazard.

The definition of a qualified person has also been revised for the 2018 NFPA 70E.

Qualified Person. One who has demonstrated skills and knowledge related to the construction and operation of electrical equipment and installations and has received safety training to identify the hazards and reduce the associated risk.

Until a person has received the safety training required to identify the hazards and reduce the associated risk that person is not considered a qualified person. Understanding the language of safety and the terms defined in Article 100 should be a part of that training.

JADE Learning offers on-site NFPA 70E classes to help you meet your electrical safety training requirements. For some states, NFPA 70E continuing education courses are also available online at www.JadeLearning.com