Top 2017 NEC Changes in Articles 100 and 110

By: Wes Gubitz | Feb 12, 2018

By: Wes Gubitz

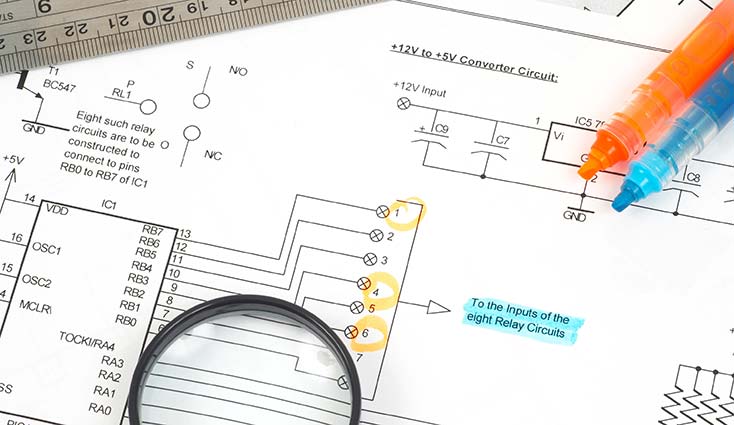

I have been an electrical instructor for a local community college for more than 15 years. I encourage every student to become familiar with the language we use in the electrical trade because let’s face it… we have our own language. Some of it is trade slang passed down to us from our mentors and co-workers, but most of it is a formal language that must be understood for its proper application. The National Electrical Code, the Code, has a formal vocabulary that is used universally by everyone associated with electrical installations, whether residential, commercial, or industrial. We all need to become familiar with the vocabulary used in the Code.

Article 100

Article 100 is where you will find definitions “essential to the application of this Code.” A change that can be found in the Scope that you will see applied throughout the Code is the high voltage threshold. The high voltage threshold of equipment operation has been raised from 600 volts to 1000 volts.

Another change in Article 100 is in the definition of “readily accessible.” This is one of the top changes in the 2017 NEC as it now considers the use of “keys” meeting the definition of “readily” accessible. Prior to this edition, a key was considered a tool, and an enclosure that required a key for access was not considered readily accessible, even if it met all the other requirements of being readily accessible. This could have a great impact on how we access control panels and enclosures going forward keeping in mind that we will still need to meet all the requirements of the NFPA 70E, The Standard for Electrical Safety in the Workplace.

One last note before leaving Article 100: a new change identifies the Code-Making Panel associated with each definition. For example: (CMP-1) following readily accessible, refers to Code-Making Panel No.1, of which Article 100 falls under their responsibility when considering changes.

Article 110

There are several changes to Article 110 that will have a direct and immediate impact on the installation and service of electrical equipment. Article 110.14(D) Electrical Connections, Installation requires the use of a “calibrated” torque tool to be used any time a manufacturer provides a numeric tightening torque value in the installation instructions or on the equipment. There is allowance to use an alternative method if the manufacturer has provided one that will achieve the same results. Terminations must be properly torqued to the value specified by the manufacturer using a calibrated torque tool.

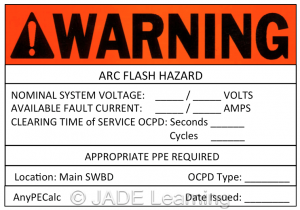

One of the changes in 110 involves Arc-Flash Hazard Warning for service equipment rated 1200 amps or more in other than dwelling units, 110.16(B). The service equipment marking must meet the general requirements of 110.16(A) that apply to all electrical equipment when conditions may require working on or around them while energized; they must be field- or factory- marked to warn qualified persons of potential electric arc hazards. This permanent label must also meet the requirements of 110.21(B) that applies to all Field-Applied Hazard Markings and include the following information:

- the nominal system voltage,

- the available fault current at the service overcurrent protective devices,

- the clearing time based on the fault current at the service equipment,

- and the date the label was applied.

Further information concerning acceptable industry practices and guidance in electrical safety and arc-flash hazards can be found in NFPA 70E, The Standard for Electrical Safety in the Workplace.

The last change we will discuss is a new section that concerns working space about electrical equipment, 1000 volts, nominal, or less to ground, with limited access that may require the equipment to be worked on while energized, 110.26(A)(4)(a-d). The following shall apply for equipment operating at 1000 volts or less to ground that is likely to require “examination, adjustment, servicing, or maintenance while energized,” whether by function or instruction from the manufacturer. If the equipment is installed in a lay-in ceiling, there must be an access hole of at least 22” x 22”, if the equipment is installed in a crawl space, a hole of at least 22” x 30” with both requiring a working space the width of the panel or enclosure or 30”, whichever is greater; all equipment doors must be capable of opening at least 90 and the space in front of the enclosure must maintain the working space of Table 110.21(A)(1).

These are just a few of the changes to the 2017 National Electrical Code in Articles 100 and 110. There are many other changes throughout the Code with a few new Articles added as well. It is a rare individual that will not have to refer to the definitions or the index to determine the proper application of the Code for a specific installation, maintenance, or service of electrical equipment. I encourage each of you to always work toward being a better professional today than you were yesterday. Know your Code. To learn more about the top changes to the NEC, sign up for a JADE Learning course today.