Feeders Part 2: Overcurrent Protection

By: Dennis Bordeaux | Dec 06, 2016

The general rule in 215.3 is that a feeder overcurrent device shall have a rating not less than the noncontinuous load plus 125% of any continuous loads supplied by the feeder. Unless permitted for specific applications, such as motor circuits, the rating of the feeder overcurrent device is selected as close as practical to the allowable ampacity of the conductor. This allows the overcurrent device to protect the conductor from overheating due to overloads, as well as from ground-faults and short-circuits. However, the allowable ampacity of a conductor will seldom exactly match one of the standard ratings for fuses or inverse time circuit breakers in 240.6.

For example, the allowable ampacity of a 500 kcmil THWN aluminum conductor in Table 310.15(B)(16) is 310 amps. The ampacity of the conductor falls in between the standard overcurrent device ratings of 300 amps and 350 amps in section 240.6. Section 240.4(B) allows the next higher standard overcurrent device rating to be used as long as the standard rating does not exceed 800 amps. So, a 350-amp overcurrent device can be used to protect the conductor provided the noncontinuous load plus 125% of the continuous load does not exceed the conductor ampacity of 310 amps.

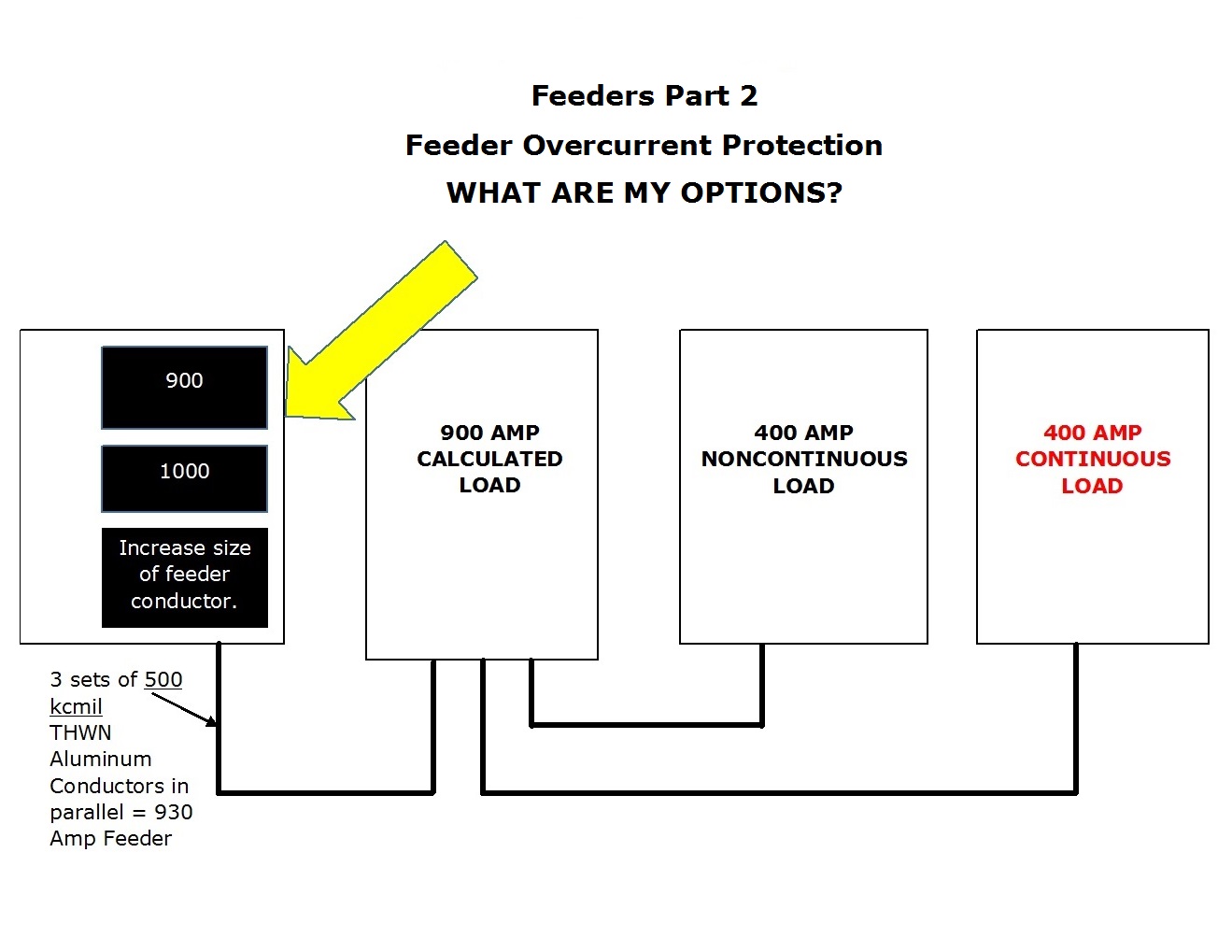

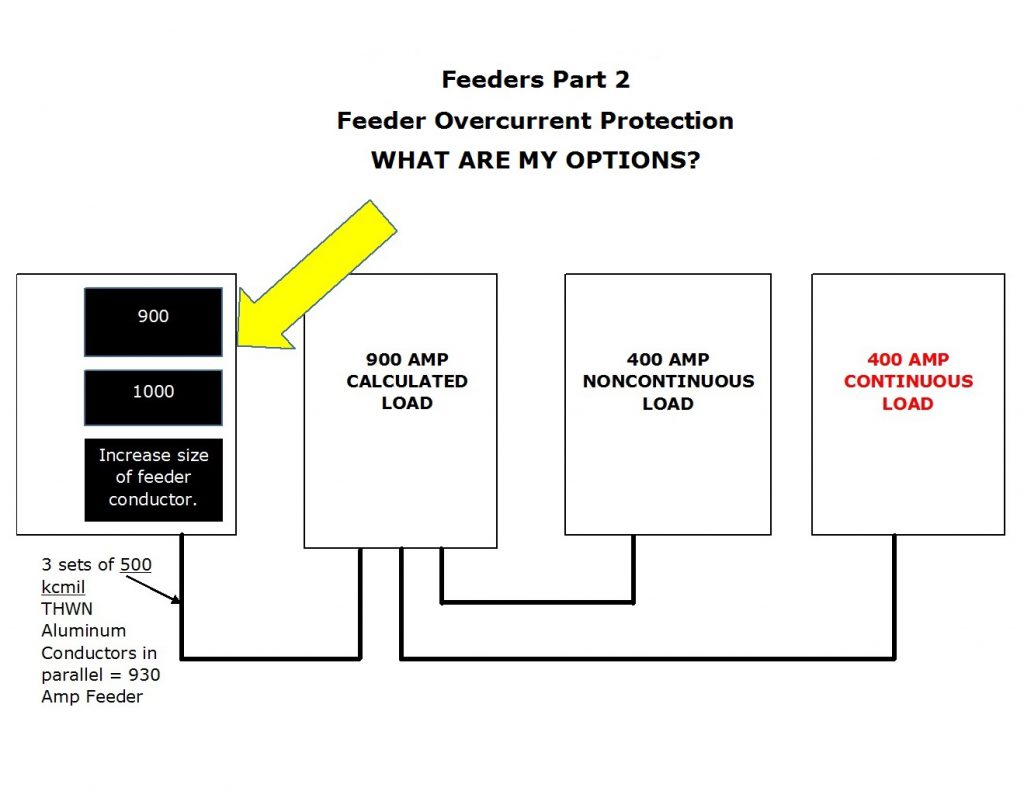

With large feeders where conductors are often connected in parallel, selecting the rating for the feeder overcurrent device is not as simple. Assuming there are not more than 3 current-carrying conductors in a raceway and the ambient temperature is 86oF (30oC), the allowable ampacity of three 500 kcmil THWN aluminum conductors connected in parallel is, 310 amps X 3 = 930 amps. The ampacity of the feeder conductors falls between the standard overcurrent device ratings of 800 amps and 1000 amps in 240.6. The next higher rating (1000 amps) cannot be used to protect the conductors because it is over the 800-amp limit set in 240.4(B), but an 800-amp rated overcurrent device may not be large enough for the load served.

For example, if the feeder supplies 400 amperes of continuous load and 400 amperes of noncontinuous load, the feeder overcurrent device must be rated not less than the 400 amps of noncontinuous load plus 125% of the 400 amps of continuous load.

400 amps of continuous load X 125% = 500 amps

500 amps + 400 amps noncontinuous load = 900 amps

A minimum overcurrent device rating of 900 amps is required, but 900 amps is not one of the standard ratings listed in 240.6.

What are the options?

1.One option is to change to a conductor with an allowable ampacity of at least 1000 amps and use a standard 1000-amp overcurrent device. The allowable ampacity of a 600 kcmil THWN aluminum conductor in Table 310.15(B)(16) is 340 amps. The ampacity of three 600 kcmil conductors in parallel is 340 amps X 3 = 1020 amps. A 1000-amp rated overcurrent device can now be used to protect the feeder.

2. A second option is to use a nonstandard rated fuse or inverse time circuit breaker rated not less than the 900 amps required for the overcurrent device and not more than the 930 amps allowed by the conductor ampacity. Section 240.6 specifically permits the use of fuses or inverse time circuit breakers with nonstandard ampere ratings, but fuses or circuit breakers with non-standard ratings may not be readily available.

3. Exception No.1 to 215.3 offers a third option that would allow an 800-amp overcurrent device to be used at 100% of its rating, but only if the entire assembly including the overcurrent device(s) protecting the feeder(s) is listed for operation at 100% of its rating. Standard overcurrent devices, panelboards and switchgear are not listed for operation at 100% of their nameplate rating so this would likely require special ordering the equipment.

Any one of the three options above provide an acceptable level of overcurrent protection for general applications. Selecting an overcurrent protective device for specific conductor applications, such as a motor feeder, is a topic for another day. Power your career by learning more about overcurrent protection and the electrical code at JadeLearning.com.