Bonding Corrugated Stainless Steel Tubing (CSST) Gas Pipe

By: JADE Learning | Apr 04, 2013

Corrugated stainless steel tubing (CSST), is used to convey flammable gas inside or outside of a building. It is not mentioned in the 2011 NEC by name, but Informational Note No. 2 to 250.104(B) cites NFPA 54, the National Fuel Gas Code, as a source for additional information for gas piping systems. This document requires that CSST gas pipe to be bonded to the premises electrical grounding system. Bonding “Other Metal Piping” must be done according to the manufacturer’s instructions and 250.104(B).

CSST is typically yellow-clad and sold in 75 ft. coils with an inside diameter of ¾ inch. The tubing is a user-friendly alternative to the black steel pipe that often had to be cut and threaded in the field. While it is rugged, corrosion-resistant and generally trouble free, there have been instances of puncture due to lightning strikes. Lightning may damage the pipe by means of a direct strike or induced current.

Either way, bonding the CSST pipe to the premises grounding system, if it is done correctly, is a highly effective way to prevent damage to the gas tubing. As always, the NEC provides guidance. Here are some basic principles for bonding CSST:

• All grounding electrode systems are to be bonded together in accordance with Section 250.50.

• The bonding conductor is to be as short as possible to limit its impedance and exposure to physical damage.

• The bonding conductor is to have as few bends as possible. The bend resembles a part turn in a coil, increasing inductive reactance and raising the overall reactance of the bonding

conductor. An Informational Note in Section 250.4(A)(1) states: an important consideration for limiting the imposed voltage is the routing of bonding and grounding electrode

conductors so that they are not any longer than necessary to complete the connection without disturbing the permanent parts of the installation and so that unnecessary bends and loops are avoided.

• The bonding conductor is to be a minimum of 6 AWG copper or 4 AWG aluminum or copper-clad aluminum. Where used outside, aluminum grounding electrode conductors are not to be

terminated within 18 inches of the earth. Section 250.64(A) and this basic principle should be applied to the installation of bonding conductors as well.

• Listed bonding clamps are to be used on the CSST. Section 250.8 has a list of permitted methods for the connection of grounding and bonding equipment. Some of these will not

accommodate the 6 AWG bonding conductor, so the best choice is to use listed pressure connectors. Avoid the connection of dissimilar metals which can lead to corrosion.

Post written by David Herres.

A special thanks to Mark Harris with CSST Saftey for the photo.

Visit www.jadelearning.com for electrical continuing education.

Great post. I had no idea about the importance of this but now I know what to look for. It’s worth the small amount of effort to protect gas piping from lightning damage.

Thanks Jon! If you have more interest in grounding and bonding topics, you can find more information in our course on electrical grounding and bonding.

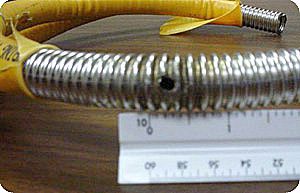

While I agree with most of what you wrote, I have an issue with the picture of the CSST with the “lightning strike” hole. That hole is indicative of a low energy, slow electrical arc, such as you would find when a energized wire was pressed against it. A lightning strike would leave a very clean, typically tiny hole at the arc point. This is due to the very high voltage and high speed of the current flow that causes the metal to vaporize. As the thinwall tubing has less mass than iron pipe the hole tends to be much larger, but still typically less than 1/10″. And since CSST is usually used in 2PSI systems, more pressure is pushing the gas out through the hole. (You cannot run @2PSI gas in iron pipe as it has tiny leaks at every joint, it is limited to 7″ to 8″ of water column(1/4PSI))

Also CSST is available in 25′ rolls, 100′ rolls, 250′ rolls, etc.

Thanks for the information Ratib! I added another photo to show lightning damage.

No insurance no license make the gas company sign in writing that they want there piping bonded to the electrical system. the city the inspector the gas company will be held harmless you will be on the witness stand all by yourself when the building blows up’

When did this bonding requirement become effective?

Informational Note No. 2 that references the National Fuel Gas Code was new to the 2011 National Electrical Code. The reference has been updated in the 2014 NEC to reference the 2012 National Fuel Gas Code.

Section 250.104(B) that requires other metal piping, including gas piping that is likely to become energized, to be bonded to the building grounding system has been in the NEC for a number of years.

CSST gas piping was introduced in the US in 1990. There were several instances when lightning caused a rupture in the CSST piping and started a fire. Manufacturers now require the CSST to be bonded to the electrical service grounding electrode system with a bonding jumper that is not smaller than 6 AWG copper.

The Authority Having Jurisdiction has the final word on how and where the CSST piping is bonded.

If anyone has examples of gas meters “blowing up” due to bonding where the gas line enters the building, I would sure like to see them. I am aware of the csst failures.

Does the ground wire have to go to the panel or can it go to a ground water pipe?

Section 250.104(B) tells us where we are permitted to make this connection. “Gas piping, that is likely to become energized shall be bonded to any of the following:

(1) Equipment grounding conductor for the circuit that is likely to energize the piping system

(2) Service equipment enclosure

(3) Grounded conductor at the service

(4) Grounding electrode conductor, if of sufficient size”

(5) One or more grounding electrodes used

Can I place a ground rod and run a 4′ # 6 wire to the pipe

as the electrical panel ground is aprox. 50 foot away at the

opposite end of the pole building. Using Propane.

Ray