Electrical Safety in the Workplace (2018 NFPA 70E)

By: Dennis Bordeaux | May 07, 2018

The 2018 edition of NFPA 70E, Standard for Electrical Safety in the Workplace has been extensively revised and significant new requirements have been added.

Electricity is the most pervasive energy source present in the workplace and can present an extremely dangerous hazard to those who must work in proximity to energized conductors or energized circuit parts. The U.S. Bureau of Labor Statistics reports that there were approximately 6000 fatal electrical injuries in the twenty- year period from 1992-2012. The total number of fatal and nonfatal electrical injuries during this period exceeded 30,000. The number of electrical injuries, especially to employees in the construction and maintenance occupations led OSHA to make electrical safety in the workplace one of its top priorities.

The number of fatal injuries has fallen steadily each year as employers have implemented electrical safety-related procedures to meet OSHA’s performance based electrical safety standards. The most basic performance requirement is the employer’s general duty to provide a workplace that is free from recognized hazards that may cause an employee to suffer death or serious injury.

Although OSHA standards include some specific electrical provisions, OSHA relies on employers to implement an electrical safety programs based on national consensus standards. NFPA 70E is the preeminent standard for electrical safety in the workplace. OSHA does not require compliance with NFPA 70E, but has consistently recognized compliance with the prescriptive requirements in NFPA 70E Standard for Electrical Safety in the Workplace as the performance goal of providing an electrically safe work place.

Electrical Safety Program

The keystone of an employer’s compliance with NFPA 70E is the electrical safety program implemented to protect employees from recognized electrical hazards. Although the standard has effectively required an electrical safety program since it was first developed in 1976, prior to the 2018 edition NFPA 70E did not clearly define what the components of an electrical safety program are. The following definition of an electrical safety program is not found in Article 100:

Electrical Safety Program. A documented system consisting of electrical safety principles, policies, procedures, and processes that directs activities appropriate for the risk associated with electrical hazards.

The important term here is “documented system.” The electrical safety program is a system where the components work together to eliminate or reduce electrical hazards to the maximum extent possible. The key elements that must be included in the electrical safety program are found in Section 110.1 of the standard. have been extensively revised for 2018 and 7 new components have been added.

The Big 7 – Seven New Additions to the Electrical Safety Program

NEW-110.1(B) Inspection.

The electrical safety program must now include; elements to verify that newly installed or modified electrically equipment or systems have been inspected to comply with applicable installation codes and standards prior to being placed in service. Although in some cases a local electrical inspector will inspect newly installed building wiring, this inspection often stops at the equipment disconnecting means. When equipment is modified or replaced in an industrial location there may not be any outside inspection. The employer is responsible for ensuring that a qualified person has checked the installation for compliance with the NEC and other applicable standards. This inspection should be documented as part of the electrical safety program.

110.1(H) Risk Assessment Procedure.

Two new sections have been added to the risk assessment procedure

NEW-110.1(H)(2) Human Error.

The potential for human error must now be included in the risk assessment procedure. Article 130 Working Involving Electrical Hazards risk assessments to be performed anytime an employee will be exposed to a shock hazard or an arc flash hazard. Human error is the root cause of many injuries. The potential for human error will vary depending on the task to be performed, the work environment, and the physical state of the persons involved. A new informative annex, (Annex Q) has been added to provide guidance with understanding the factors that affect human performance.

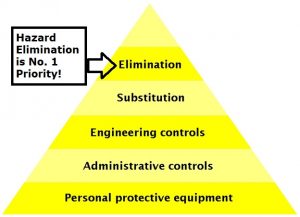

NEW-110.1(H)(3) Hierarchy of Risk Control Methods.

The hierarchy of risk control methods formerly found in an informational note is now a mandatory part of the standard. The first priority is given to elimination of the hazard and the other risk control methods must be considered in the numbered sequence to reduce the level of hazard to the maximum extent possible. PPE is the last risk control method listed to protect the employee when the hazard cannot be totally eliminated.

Hierarchy of Risk Control Methods

- Elimination

- Substitution

- Engineering controls

- Awareness

- Administrative controls

- PPE

110.1(I) Job Safety Planning and Job Briefing.

A job safety plan must be completed and a job briefing held before starting any job that exposes employees to electrical hazards. Three new sections have been added to 110.1(I).

NEW-110.1(I)(1) Job Safety Planning.

The job safety plan must be completed by a qualified person, be documented and include the following information.

- A description of the job and individual tasks

- Identification of the electrical hazards associated with each task.

- A shock risk assessment per 130.4 (if shock hazard is present).

- An arc flash risk assessment per 130.5 (if arc flash hazard is present).

- Work procedures, special precautions, and energy source controls.

NEW-110.1(I)(2) Job Briefing.

Once the employee in charge has completed the job safety plan, identified the hazards, associated risks, and the work procedures to be followed the information must be communicated to the employees who will be performing the various tasks. Each employee must have a clear understanding of what is expected and the procedures to be followed, any questions or concerns should be addressed during the briefing.

NEW-110.1(I)(3) Change in Scope.

A change in the scope of work can and often will occur after the job briefing is held. Often the change in scope be the result of conditions discovered as the work is being performed. Any change in the scope of work that affects employee safety requires additional job planning and a follow up job briefing to inform the affected employees of the changes. Even what seem to be minor changes to the scope of work can have adverse consequences.

NEW-110.1(J) Incident Investigation.

Electrical incidents include more than just those that make the news because someone was killed or seriously injured. Electrical incidents include minor shock and arc flash events that could have resulted in serious injury, but luckily did not. Relying on luck to avoid injury in the future is a poor choice. The electrical safety program must include the elements necessary to investigate electrical incidents. If the cause of the incident can be determined, measures can be taken to avoid similar incidents in the future that may have a more serious outcome.

Summary

The seven new additions to the electrical safety program required by 110.1 are just the beginning of the story. The additions and revisions in Article 110 affect requirements in the other chapters of NFPA 70E Standard for Electrical Safety in the Workplace, especially Article 130, Work Involving Electrical Hazards. Procedures need to be updated to meet the new requirements and work practices adapted. Employees must understand and utilize the hierarchy of risk assessment and include the potential for human error during when performing risk assessments. Job safety planning and job briefings must be documented. Training or re-training must be provided as procedures, processes, and safety-related work practices are adapted to meet the new requirements.

To learn more about Electrical Safety in the Workplace, visit www.JadeLearning.com.

Good morning,

I always use Jade Learning for all my electrical prerequisites and I have a maintenance coworker that Human Resources is requiring that he take a safety class. Can he take the Electrical Safety in the Work Place

(2018 NFPA 70 E) class or does he have to take all the safety classes. Please let me know what the cost is for class.

David

It depends on their requirements for the safety class – it may be something he can fulfill with that class or they may be requiring an 8- or 16- hour class which we also offer through TPC Training.

https://live.tpctraining.com/public-seminars/electrical-training/fundamentals/arc-flash-electrical-safety-nfpa-70e